Embedded AI in Manufacturing: Where Innovation Meets Excellence

Aleksandr Dolgaryev

CTO

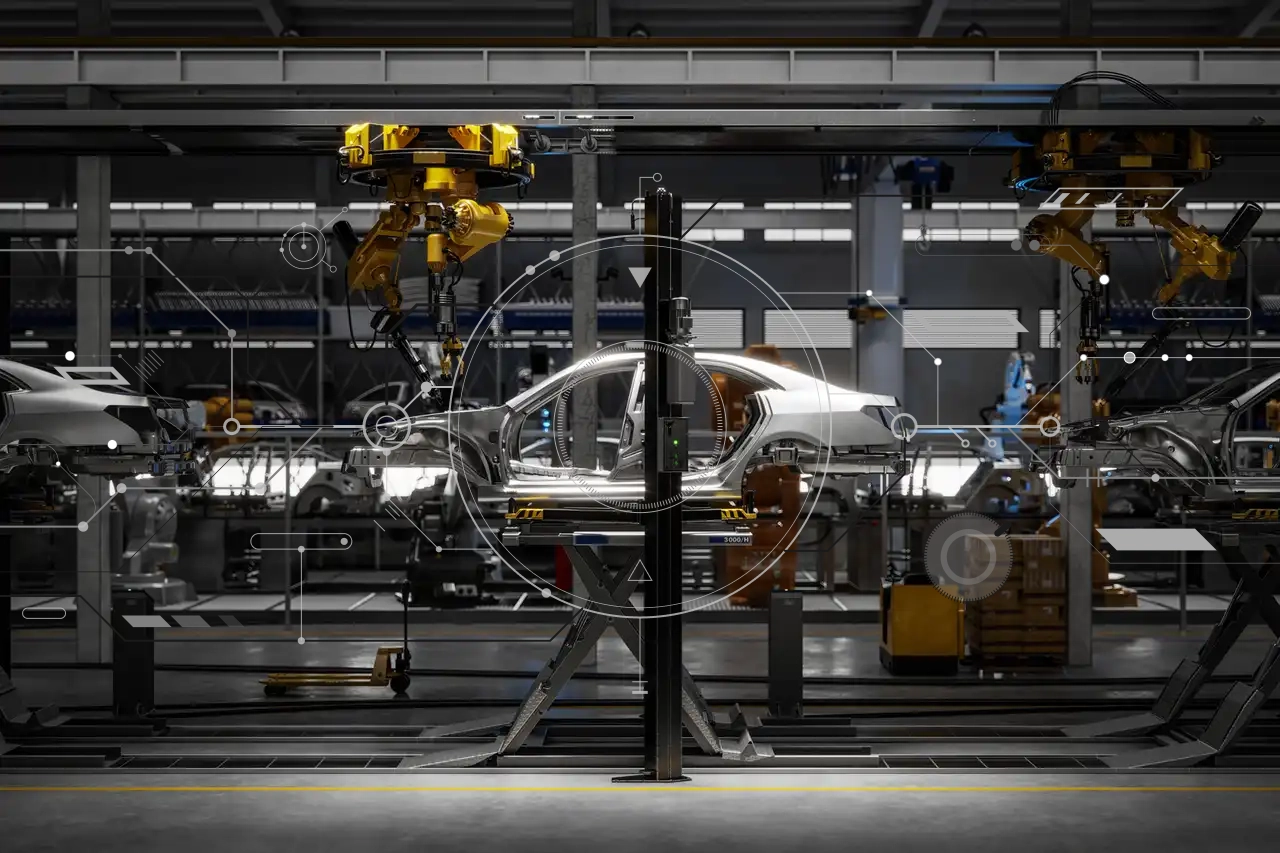

Revolutionizing Manufacturing with Embedded AI

In the ever-evolving landscape of Industrial Machinery and Manufacturing, the pursuit of efficiency and safety remains a continuous challenge. According to the Deloitte Well-being at Work survey, 85% of business leaders understand the importance of optimizing production processes while ensuring the well-being of their workforce, actively looking for trusted partners to reshape the industry’s future.

Embedded AI is a revolutionary solution that not only reduces labor work but also elevates safety standards to unprecedented heights. Today, we invite you to explore the transformative potential of Embedded AI, but let’s start from the beginning.

The manufacturing conundrum

Manufacturers have always struggled to balance productivity and safety for workers. This enduring challenge has significantly influenced industrial machinery and manufacturing. Traditional manufacturing processes often require a substantial workforce to operate complex machinery and oversee intricate operations. While this human element is indispensable, it comes with concerns:

- The Human Factor. Worker exhaustion from long hours, repetitive tasks, and physically demanding work can lead to fatigue-induced errors, causing accidents, work stoppages, and harm to workers.

- Safety Risks. Safety is paramount here, and any compromise can have severe consequences, from accidents to tarnishing a company’s reputation. The traditional approach often relies on manual safety checks, which, while well-intentioned, can be prone to oversight or human error.

So, manufacturers have long been stuck in a dilemma – how to maintain or even increase efficiency without sacrificing safety. The choice often felt like a trade-off – one at the expense of the other. The need for a solution to tip the scales in favor of both was evident.

Unparalleled benefits of Embedded AI

At Quantum, we recognize that thriving in modern manufacturing requires a paradigm shift. Embedded AI directly integrates artificial intelligence into machines and systems used in manufacturing. It’s not a separate system but an intrinsic part of the equipment, enabling it to perform tasks autonomously and make intelligent decisions.

In essence, Embedded AI infuses a layer of intelligence into the very fabric of manufacturing processes, offering a game-changing solution where AI meets machinery to benefit manufacturing. Here’s how:

Enhanced Efficiency

Embedded AI systems are adept at repetitive tasks, precision control, and real-time data analysis, reducing labor requirements and increasing production efficiency. With Embedded AI, manufacturers can produce more with fewer resources, leading to cost savings and heightened profitability.

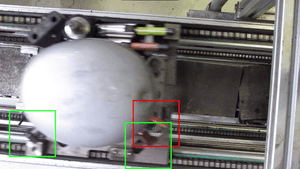

For example, Quantum developed an Embedded AI automated quality control solution that increases manufacturing efficiency by processing real-time video streams and detecting anomalies with 99.99% accuracy, reducing costs and manual work.

Safety Redefined

Safety is at the forefront of Embedded AI’s benefits. These intelligent systems can monitor equipment conditions, predict maintenance needs, and detect anomalies in real time. By proactively addressing potential issues, manufacturers can prevent accidents, reduce downtime, and create a safer working environment for their employees.

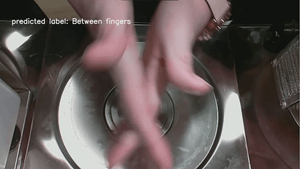

In specific manufacturing sectors, such as pharmaceuticals, maintaining proper hygiene is critical to worker safety. Strict adherence to hygiene protocols ensures that pharmaceutical products consistently meet the highest safety and efficacy standards.

Here, Embedded AI also proves its utility. For instance, Quantum developed an automated handwashing quality assessment solution that processes a video stream and analyzes hand movements, comparing them with the WHO’s (World Health Organization) recommended procedure.

Data-Driven Insights

Embedded AI generates a wealth of data, providing manufacturers with unprecedented insights into their operations. This data can be harnessed to make informed decisions, optimize processes, and uncover hidden opportunities for improvement. Quantum’s Embedded AI solutions empower manufacturers to stay ahead of the competition by leveraging data as a strategic asset.

Partnerships are Keys to Success

At Quantum, we understand that commitment to quality, precision, and safety must align seamlessly with our clients’ goals. Understanding various industries’ nuances, we tailor our Embedded AI systems to meet specific business needs. With a track record of delivering tangible results, we stand for:

Data-Backed Excellence: We don’t just make claims; we deliver results backed by data and insights. We’ve witnessed our clients achieve substantial reductions in labor costs, production efficiency improvements, and safety records enhancements. Our solutions are quality-tested and proven to elevate manufacturing to new heights.

The Future Beckons: The future of manufacturing equipment parts is being shaped by innovation. Embedded AI is leading the charge. Quantum invites you to adopt the power of Embedded AI for unparalleled efficiency and safety.

Contact us today to explore how Embedded AI solutions can revolutionize your manufacturing processes. Let us collaborate to turn your vision of a more efficient, safer, and prosperous manufacturing future into a reality.

AI Consulting

We help define relevant use cases, assess data readiness, and build AI adoption roadmaps to ensure regulatory alignment, cost-effectiveness, and measurable impact.

Check the service